Boroscopy & Thermography on Wind Turbines

Early detection of component damage by boroscopy & thermography!

Since 2004 the 8.2 GROUP has performed more than 3,000 inspections by boroscopy:

during this inspection a visual examination is made with the help of a video camera.

There is no other technique which provides a quick, secure and reliable optical examination of difficult to access areas as for example cavities or internal components of a machine.

Apart from being able to visualize the internal structure of objects the boroscopy offers the possibility to assess the condition of objects as far as possible defects are concerned. Costly stand still periods of wind turbines will be reduced if defects of components are detected during an early stage.

Inside of wind turbines, the boroscopy is mainly used for the inspection of gear boxes.

However, the 8.2 experts use boroscopy also for the inspection and assessment of generators, pressure chambers of rotor blades and other components.

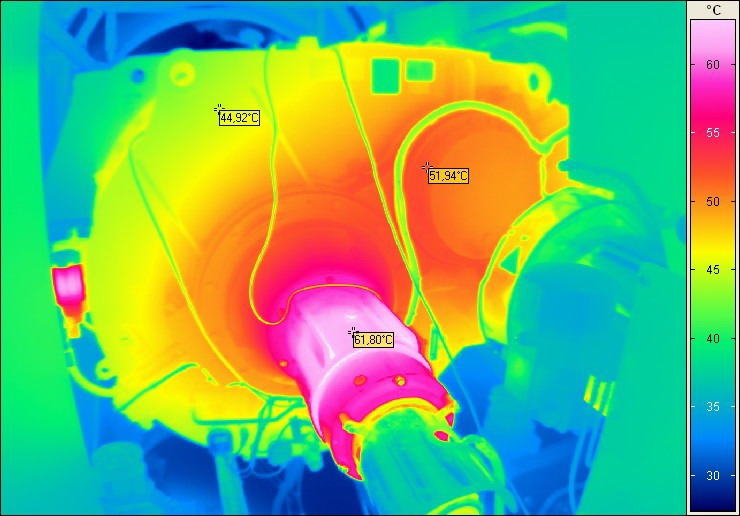

Thermography:

Easy detection of problems with cable connections

During the inspection of the electrics of wind turbines or photovoltaic plants the 8.2 GROUP uses the technology of thermography.

Thus, problems caused by cable connections installed in an inappropriate way can be detected more easily.