fleetMONITOR Software - all data streams in one software platform!

Your monitoring engineers can diagnose reliability problems quickly and effectively with the fleetMONITOR web application:

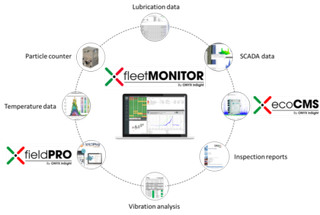

Data from vibration CMS, SCADA system, lubricant analysis, inspection and maintenance reports are analyzed within a single software platform!

The fleetMONITOR modules range from dashboard views for top-level alarms and trends to detailed vibration analysis tools for the expert analyst.

Industrial machines and wind turbines all over the world are connected to fleetMONITOR.

8.2/ONYX continuously analyzes vibration and SCADA data from many gigawatts of assets worldwide. We provide routine condition monitoring services to a large number of global operators and utilities from our monitoring centers around the world using fleetMONITOR software.

fleetMONITOR facilitates the work of our monitoring engineers and their feedback improves the software every day.

What is the reason for the software's success?

Because we use it to monitor a large number of rotating machines every day and continuously improve and refine it.

Why is the reporting such a success?

Because we have to generate a large number of reports each month and because we have streamlined the entire workflow so that all engineer comments and recommendations are accurately communicated through the software.

Scope of typical monitoring services:

- Routine analysis of vibration and SCADA

- Extraordinary reports

- Regular support including expert interpretation and recommendations

- Troubleshooting and investigation of its respective cause

Improved O & M decisions based on Big Data

fleetMONITOR selects data from ecoCMS, from third-party CMS, from SCADA databases, from particle counters, from lubricant analysis and from maintenance/inspection data and joins them in a unique database.

Description fleetMONITOR

You see an overview of all wind farms in the fleet. Each wind farm displays a simple notification by the number of red and yellow alarms, and users can see a live feed of updates and notifications such as new alarms or comments added by colleagues on the right side of the screen.

From the dashboard, the user can see an overview of all turbines in a wind farm, along with their alarm status and a summary of all currently active alarms for the site.

All customers of the 8.2 Monitoring Service use this dashboard in order to track all current alarms on their turbines as well as see and respond to live comments from the 8.2 monitoring team.

In the Trend and Health Index, high-level trends are presented that show the progression of failures. The 8.2/ONYX InSight "health indices" are powerful metrics developed over many years of conducting condition monitoring projects and refining the best possible approaches to detecting wind turbine drivetrain faults.

For condition monitoring engineers and vibration analysts, advanced tools provide detailed analysis of raw vibration data. With a focus on easy-to-use yet extremely powerful tools, fleetMONITOR enables a small team of engineers to monitor many gigawatts of assets with just a few clicks.